High performance and versatility: olimpic k 560 is designed for companies requiring to process many panels per day even though they may be different from one to another. olimpic k 560 has several solutions that guarantee always the best machining on any panel type.

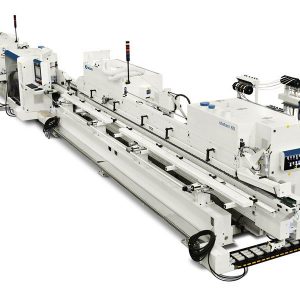

Olimpic K 560

High performance and versatility: olimpic k 560 is designed for companies requiring to process many panels per day even though they may be different from one to another. olimpic k 560 has several solutions that guarantee always the best machining on any panel type.

Advantages

Perfect joint line with the “SGP” glue pot thanks to the perfect dosing and the special spreading roller. The use ofEVA and Polyurethane glue is made possible by the anti-adherent plasma treatment and a fast and simple glue changeover.

Perfect joint line with the “SGP” glue pot thanks to the perfect dosing and the special spreading roller. The use ofEVA and Polyurethane glue is made possible by the anti-adherent plasma treatment and a fast and simple glue changeover.

Perfect results on all surfaces. The controlled axes allow all intermediate positioning of the trimming and edge scraping groups, ensuring optimal edge banding even in the case of surfaces with different degrees of roughness or panels covered with protective film. These units allow the machining of 2 different radii, endless thin edges and solid wood.

“Round X” rounding unit: productivity and quality with 2 motors technology. The features of the unit allow for the double function of both the simultaneous trimming and rounding operations. The two joint operations, in a single group, require less space and, together with the working distance between panes of only 600 mm, give a reduction in time for the edge banding.

“Round X” rounding unit: productivity and quality with 2 motors technology. The features of the unit allow for the double function of both the simultaneous trimming and rounding operations. The two joint operations, in a single group, require less space and, together with the working distance between panes of only 600 mm, give a reduction in time for the edge banding.Technical data

| Edge thickness | mm | 0,4 – 6/8 (12 opt.) |

| Panel thickness | mm | 8 – 60 |

| Feed speed | m/min | 12 – 18 |

| Compressed air | bar | 6 |