The ideal solution for batch-1 process.

Compact and smart CNC drilling centre perfect to grant drilling on 5 faces of the panel, blade-grooving and routing operations, thanks to two drilling heads, with independent Y axis, for simultaneous machining on the same panel.

No need of manual interventions to setup the machine between two operations, allowing uninterrupted machining cycle.

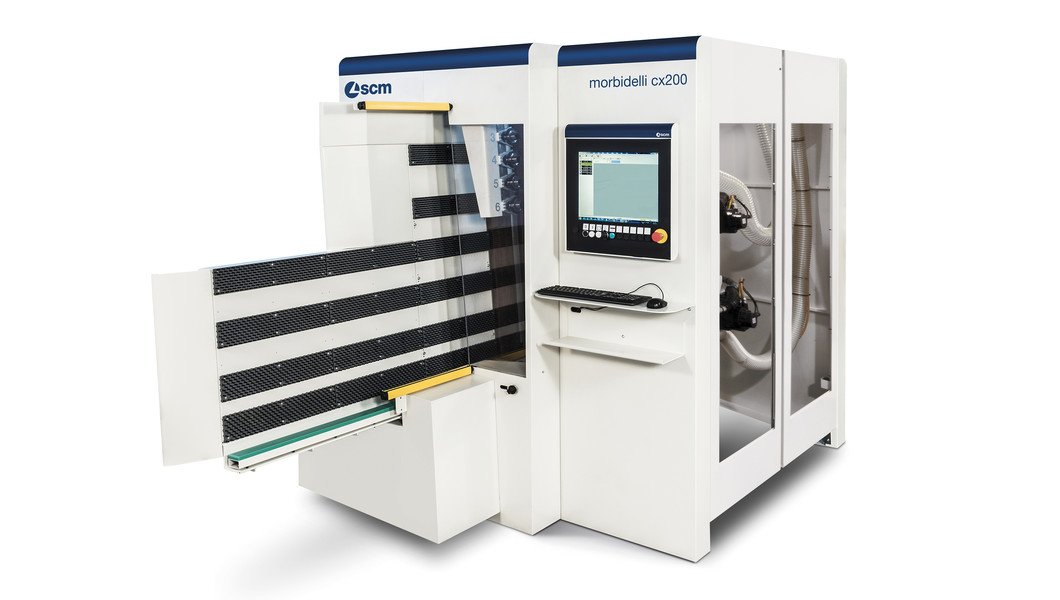

Morbidelli Cx200

The ideal solution for batch-1 process.

Compact and smart CNC drilling centre perfect to grant drilling on 5 faces of the panel, blade-grooving and routing operations, thanks to two drilling heads, with independent Y axis, for simultaneous machining on the same panel.

No need of manual interventions to setup the machine between two operations, allowing uninterrupted machining cycle.

Advantages

THE PERFECT DRILLING: RO.AX SPINDLE

Zero play during machining with the new RO.AX technology (Rotoaxial spindle technology), the most efficient spindle on the market with rotation speeds up to 8000 rpm. The sturdiness of drilling heads is proven by the reduced maintenance costs: five times less than that imposed by the majority of other machine manufacturers.

Technical data

| Workpiece max. dimensions | mm | 3050x1300x95 | ||

| Workpiece min. dimensions | mm | 200x50x8 | ||

| X-Y-Z axes speed | m/min | 70-40-30 | ||

| Drilling heads | n. | 2 | ||

| Independent vertical spindles | n. | 24 | ||

| Independent horizontal spindles X direction | n. | 8 | ||

| Independent horizontal spindles Y direction | n. | 3 | ||

| Electrospindle motor power | kW | 6,6 | ||

| Tool changer positions | n. | 6 | ||